Monuments to the complicated history of the American South don’t just take the form of statues in city squares; they also include large-scale public works projects. A case in point is the Augusta Canal National Heritage Area, in Augusta, Georgia, established by the U.S. Congress to preserve the Augusta Canal and its environs. The Augusta region emerged in the 19th century as the South’s preeminent industrial zone and, briefly, a crucial cog in its production of supplies for the Civil War. But the canal site — including many large surviving textile mills — reveals a more complicated story. It was also a testament to the unsung laborers, including free and enslaved Black workers, who helped build it.

In the 1977 Historic American Engineering Record report on the canal, HAER GA-5, historian Robert L. Spude quoted the 1918 book American Negro Slavery, by Ulrich B. Phillips, who described the chaotic scene from about 1827 in Augusta, which was establishing itself as a regional trade center: “The thoroughfares were thronged with groaning wagons, the warehouses were glutted, the open places were stacked, and the steamboats and barges hidden by their loads.” Fueled by their chief commodity, cotton, Augustans believed their city was destined to soon rival Philadelphia.

But Augusta faced competition from other cities — Atlanta, Macon, and Columbus in Georgia and Hamburg, South Carolina, on the other side of the Savannah River — and between 1830 and 1840 the city’s population actually dipped a bit. For years city leaders had been mulling the idea of building a canal along a stretch of the Savannah River that ran through Augusta. Spude noted that small factories had begun to pop up along the creek banks on the outside of town as city leaders speculated about “harnessing the falls of the Savannah, a few miles above the city, and thus providing power sufficient for innumerable mills.”

The goal was to become the South’s version of Lowell, Massachusetts, the center of the American Industrial Revolution. This, too, was an idea that had occurred to rival cities in the South. Throughout the 1830s and ’40s, Spude wrote, “Southern urbanites sought to transform their cities into prosperous centers.” People who dreamed of becoming industrialists set up in towns along the Piedmont, the plateau between the Appalachian Mountains and the Atlantic coastal plain, and those towns “became, or strove to become, manufacturing centers.”

The key figure who drove Augusta’s ambitions was Henry H. Cumming, director of the Georgia Railroad and Banking Co. and member of a prominent Georgia family. In 1844, determined to lead the efforts to build a canal, he hired the chief engineer of the Georgia Railroad, John Edgar Thomson, and local surveyor William Phillips “to determine the fall of the Savannah from Bull Sluice, at the beginning of the falls some six miles from town, to the mouth of Hawks Gully, or Augusta’s western city limit,” Spude wrote. The two concluded that the river fell 52 ft over the course of 6 mi, potentially creating enough power to drive cotton mills.

By 1845, Augusta’s four banks had pledged $4,000 to pay for a more comprehensive survey, which Thomson again oversaw. Thomson, who would later become the chief engineer and the president of the Pennsylvania Railroad, knew his way around canals; his father had overseen work on the Chesapeake and Delaware Canal in Delaware.

According to Patrick M. Malone’s 1976 book, The Lowell Canal System (as relayed in the HAER report), “The ideal way to supply a number of mills with water power is to use a single canal running parallel to a river with a falls. If the canal leaves the river above the falls and reenters at some distance downstream, then the land between the canal and the river becomes an extended island on which mills can be placed in a line. By keeping the level of water in the canal close to that of the river above the falls, there will be a major difference in water level between the canal and the river at every point below the falls.”

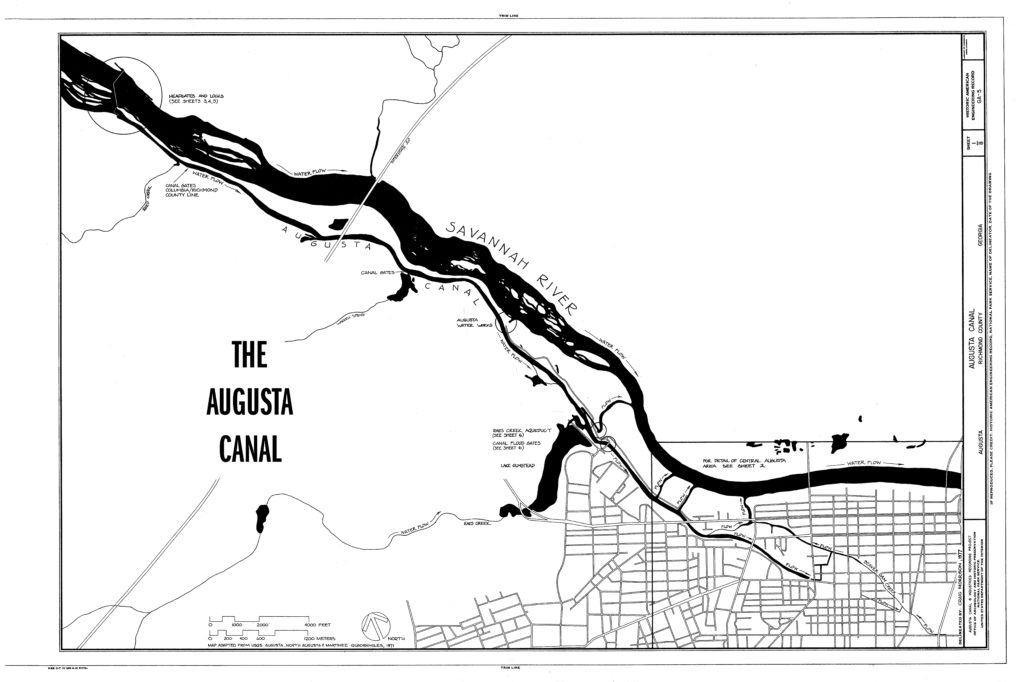

The plan for the Augusta Canal was for it to be built just south of the river and extend into the center of the city. Its configuration, Spude wrote, resembled a “three-pronged fork with an off-center handle and prong tips bent until touching.” The canal ultimately consisted of three levels. A wing dam would channel water from the river at the head of the falls into the first and longest level of the canal to “industries along its eastern bank, then fall through water wheels or turbines and come out at the second level 13 feet lower. From the second level the water again fell 13 feet through mill power machinery to the third level. The third level, actually a widening and connecting of Beaver Dam Creek and Hawks Gully, carried the spent water to the Savannah River.”

Cumming was aware of the stock company financing of canals that was common in New England as well as the government-subsidized funding common in Europe, and he combined the two ideas in his Augusta Canal proposal. A stock company, the Augusta Canal Co., would supervise construction of the canal; the city of Augusta would buy the stock by transferring $100,000 in city bonds to the canal company. The sale of the bonds would finance the canal’s construction. Additionally, in exchange for a tax on city real estate, citizens would receive a proportionate amount of stock, or “Canal Scrip.”

“The plan straddled the legal domain of both a private corporation and the city government,” Spude wrote, “but lawyer Cumming judged that all was legally sound.”

The incorporation bill raised eyebrows in the Georgia legislature. One member called the bill “the strangest one he ever saw,” and some merchants and other property owners unsuccessfully contested the financing’s legality in court. But the plan passed in 1845; the city council’s only addendum was that the canal also supply the city with sufficient potable water.

Cumming hired civil engineer C.O. Stanford to oversee construction. Descriptions of canal construction methods were scarce in newspapers of the day. Some reports, Spude wrote, suggested that “explosives were used to cut through rocky sections, that slaves and whites from the hills of north Georgia composed the labor force, and that masons from the North built the culverts, aqueducts, and head gates. In short, construction of the Augusta Canal was slow and primitive.”

Workers came from all over: local white laborers, Georgia Railroad workers, and African American workers, both free and enslaved. According to the Augusta Museum of History, free Black men made up a large portion of the labor force in river towns like Augusta; they typically held jobs as stevedores, boat operators, and sometimes even riverboat captains.

The project crossed the plantation of Judge Benjamin H. Warren. Spude’s history says that the judge had a “force of hands and teams clearing the grade.” His brother-in-law, James L. Coleman, put 70 enslaved people to work on the project. As the New Georgia Encyclopedia notes, the summer heat “decimated the white work crew, and Black labor — slave and free — finished the job.” At least 50 free Black workers were also hired and paid $85 for a year of work — about the same rate as white laborers brought in from Savannah and Charleston, according to Edward J. Cashin’s 2002 history of the canal, The Brightest Arm of the Savannah: The Augusta Canal 1845-2000.

The museum adds that Black workers, bearing the brunt of that harsh Augusta summer, dug the first level of the canal by hand. By November 1846, about 200 workers had completed the first level of the canal. But it wasn’t until the arrival of entrepreneur Jacobez Smith in 1847 that the financial fortunes of the city began to change. Smith had helped transform Petersburg, Virginia, into an industrial center, and he began to do the same in Augusta, building a pair of mills that eventually became the Augusta Manufacturing Co., one of the largest mills in the South.

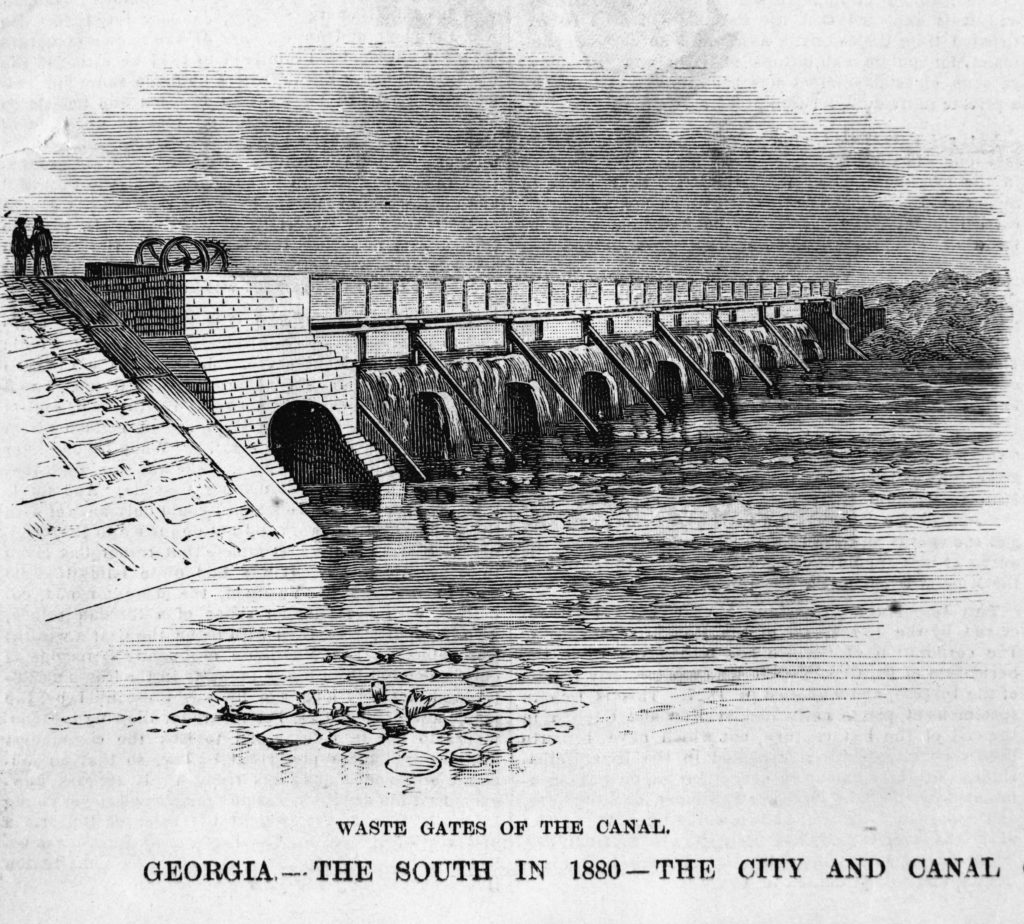

Workers continued to flock to the city. In 1848, William Phillips took over as chief engineer on the canal, a position he held for the next 25 years. He completed the second and third levels and enlarged the wing dam. “By 1850, he had crews bolting the finishing timbers atop the cribwork dam,” Spude wrote, “which increased the depth of the first level from 5 feet to 6 feet.” Iron gates were installed downtown to prevent the increased flow of water from flooding the city.

Phillips also enlarged the canal between 1855 and 1857, capping the riverbanks with timber, riprap, and stone. The worm gears of the canal’s head gates were replaced with rack-and-pinion gearing, making it easier to raise and lower the wooden panels. This work was done largely by Irish laborers, making $1 a day, and free Black laborers, making $0.85 a day.

Two old wooden aqueducts, which had begun to lean and collapse, also had to be torn down and replaced. And there were other problems for Phillips, Spude relayed, including “breaks in the canal bank, silt build-up, and users’ complaints of low water.” He also had to deal with at least one lock keeper who had to be fired from his position due to “excessive inebriation.”

The enlarged canal served the city during the Civil War; the Confederacy established a 2 mi long munitions factory, the Confederate Powder Works, along its bank. Other manufacturers joined, including a dye plant, a bakery, and a pistol factory. According to the National Park Service, the Powder Works was the only permanent structure built by the Confederacy; it turned out 2.75 million lb of gunpowder — 7,000 lb a day. It was, according to a video documentary produced by the Augusta Canal National Heritage Area, “the most efficient gunpowder plant in the world.”

In one of countless bitter ironies, many of the jobs around the Powder Works were performed by enslaved Black workers, including “hauling and chopping wood for the boiler furnaces, burning coal, and moving finished gunpowder down the canal by mule-drawn boats,” according to the Augusta Canal National Heritage Area, which cites the 1974 book Confederate City: Augusta, Georgia, 1860-1865 by Florence Fleming Corley (University of South Carolina Press).

After the war, the federal government confiscated and later sold the land, and a subsequent widening of the canal demolished all but the Powder Works’ smokestack, which was left as a war memorial. The city languished again until Mayor Charles Estes spearheaded a three-year expansion of the canal zone. He hired a former Erie Canal engineer, Charles A. Olmstead, to supervise the work. The construction firm John A. Green & Co., also relocated workers to Augusta. According to Spude, workers used “a steam-powered dredge, vertical steam ‘donkey’ engines, and other updated equipment to dig the canal, quarry stone, and take dam materials across a narrow-gauge track to the Savannah River.”

Once again, a diverse labor force did the work, including African Americans, Irish Americans, Italian Americans, and newly arrived Chinese Americans. Spude noted that Italian American workers completed the “precise stonework” required to renovate an aqueduct at Rae’s Creek, “while the backbreaking menial labor was performed by convict labor crews made up mostly of Blacks, and by (recent) Chinese arrivals in the country.”

Not until 1877, when national money markets began to loosen up and cotton values began to increase, did prosperity return to Augusta. The population doubled between 1870 and 1890, leading to an era of impressive architectural design. One mill, for the John P. King Manufacturing Co., featured a “massive central stair and water tank tower reminiscent of the villa towers of northern Italy,” according to the HAER GA-15 report, written in 1977 by historian Alan J. Steiner. “The tower was covered with ornamental brick-work, which divided and accentuated each of its upper stories. A variety of windows and door openings, ranging from segmental to round-arched to circular, pierced the tower.”

On the remains of the Powder Works, a massive new structure, the Sibley Mill, was built between 1880 and 1882. With its “crenelated facade and corner towers,” it resembled a medieval castle, in the words of the NPS.

The years that followed were when Augusta truly became the Lowell of the South. It was an era of extremes that saw both the introduction of electrification and the development of “mill villages,” where factory workers, many of them women and children, worked nearly 12-hour days in the textile mills, leading to years of labor unrest.

Between 1880 and 1930, Spude wrote, 12 major industrial complexes used the canal’s water power. But gradually, as the 20th century got underway, the canal declined. Floods in the 1920s and ’30s damaged the canal system. Mills sought cheaper labor or lower costs and departed. In the 1930s the federal Works Progress Administration deployed hundreds of workers to renovate the zone, raising the riverbanks, straightening the canal, and constructing a new spillway, according to the Augusta Canal National Heritage Area and a drawing from the Cashin book.

During the 1960s and ’70s, the physical form of the canal and the adjacent industries changed greatly. Every industry on the second and third levels, which once ran on water power, stopped using their turbines. Many mills closed and were torn down. The city even considered draining the canal and turning it into a highway.

But preservationists imagined converting the area for recreational use and preserving its stock of industrial structures. The site and its mills were listed on the National Register of Historic Places, and Congress designated the Augusta Canal as a National Historic Landmark. The Georgia state legislature created an oversight body, the Augusta Canal Authority, in 1989 to revitalize the district; Congress designated the canal a National Heritage Area in 1996. Since then, the canal zone has become a popular draw among tourists and recreationists. And ASCE designated the Augusta Canal as a national Historic Civil Engineering Landmark in 2018.

The Sibley Mill produced textiles as recently as 2006 before closing; the building still generates electricity. Developers are looking at converting the Sibley and King mills into mixed-use projects. Another, the Enterprise Mill, has been converted into an office, residential, and museum complex.

The Augusta Canal still provides the city’s water supply and, as a symbol of an economy dominated by tourism and services, may yet lead a new renaissance in Augusta.

This article first appeared in the May/June 2021 issue of Civil Engineering as “Powering the South: The Augusta Canal.”