ENGINEERS, architects, and other designers are rapidly working with health-care experts on a range of efforts to help expand the nation’s supply of hospital beds. These endeavors are in addition to those being undertaken by the U.S. Army Corps of Engineers, which is converting several public spaces into care facilities in some of the United States’ hardest-hit cities.

One of the chief emerging strategies involves the conversion of otherwise idle hotel rooms. There are more than 5 million guest rooms in the United States, according to the American Hotel and Lodging Association, of Washington, D.C., and virtually all of them are sitting empty.

In early April, designers at Dallas-based HKS published a report examining the viability of converting hotels for use as temporary hospitals. The firm’s research found that convention center hotels—which typically have 500 rooms or more—provided the most versatility. They have existing facilities to handle laundry and food service, room for triage spaces, and sufficient back-of-house space for the delivery of critical supplies, the report concluded.

A number of questions need to be answered before using hotels for the most critically ill COVID-19 patients, according to Chad E. Beebe, AIA, a certified health-care facility manager and the deputy executive director of advocacy for the American Society for Health Care Engineering. Among the questions, he says, is how to supply oxygen for those who need ventilators. People will trip if hoses run along the floor, he points out, and “you can’t drill big holes in the wall to add this stuff.”

But hotels make sense for other uses. They can serve as respite sites for health-care workers, temporary care centers for those with less severe symptoms, or living quarters for symptom-free people who test positive for the virus and need to avoid family members at home.

Convention center hotels also often include ballroom spaces, which can be used for “visual monitoring” of many patients at once, Beebe says. Such spaces are also large enough for equipment like ventilators and backup generators that may be needed for higher-acuity cases. Larger hotels also offer health-care planners the opportunity to “flex” spaces, designating certain floors for caregivers and others for patients, he points out.

Controlling the Air

The HKS study calls for a series of tweaks to hotels to ensure that rooms used for patients handle their existing heating, ventilation, and air-conditioning (HVAC) systems appropriately. Designers must ensure that air doesn’t recirculate to other parts of the hotel, and air quality can be improved with the addition of high-efficiency particulate air (HEPA) filtering units. The study also notes that upgrades to hotel power systems may be required if those facilities do not already have emergency power supplies.

Standard hospital rooms can be converted for use in treating COVID-19 patients with the installation of high-efficiency particulate air-filtering systems. (Courtesy of Thornton Tomasetti)

Standard hospital rooms can be converted for use in treating COVID-19 patients with the installation of high-efficiency particulate air-filtering systems. (Courtesy of Thornton Tomasetti)

Jennie Evans, RN, LEED AP, the development director for HKS and one of the authors of the report, notes that using hotels for health care presents important questions that will have to be answered to prepare for future health crises as well. “There will be policies that will have to be looked at,” she says. “How do you train hotel staff to safely manage low-acuity patients who might be infectious? How do you clean the hotel, during and after? Will hotel staff have to be trained in the use of PPE [personal protective equipment], [and] will that be an annual training for them?”

Linking Hospitals to Hotels

In early April, the Center for Health Design, a Concord, California-based nonprofit that studies and advocates for improvements to the design of health-care spaces, launched MakingRoom, a database that links hospitals with hotels. The goal, says president and chief executive officer Debra Levin, was to “create a matching service that would help hotels that are struggling right now and have capacity to match up with hospitals in need of space.” When Civil Engineering first spoke with Levin, in early April, there were fewer than 20 hotel listings. By April 17, there were more than 125.

Levin says that even for-profit companies are looking at pursuing what she calls “mission and margin,” trying to answer the question so many businesses are asking: “How can they both help and keep their people employed and their organizations alive and surviving all of this?”

And hotels aren’t the only potential solution. HKS, for one, is also looking at converting high schools for low-acuity patients—particularly in smaller cities or rural communities that may lack large convention-center-style hotels.

Making It Modular

Other design firms are considering a tried-and-true method for expanding bed capacity: modular prefabricated construction. “It’s real,” says Kurt Spiering, FAIA, ACHA, a principal and the health-care sector leader for the Minneapolis-based engineering and architecture firm HGA. “It’s proven tech we’ve adapted into that critical-care environment to meet a specific need for COVID-19 patients.”

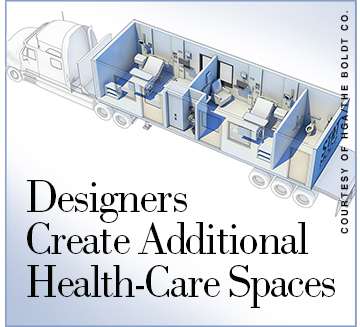

HGA and Boldt Co., a construction services firm based in Appleton, Wisconsin, have been working together since mid-March to adapt existing prefab technology to meet the new crisis. The result is a modular unit dubbed the STAAT Mod; STAAT stands for strategic, temporary, acuity-adaptable treatment. At the time of publication, HGA was able to build two such modules per day.

The STAAT Mod hospital rooms can be quickly installed inside such unused

public spaces as convention centers or arenas. (Courtesy of HGA/The Boldt Co.)

Fabrication partners across the country are “ready to go when the volume increases,” says Kate Mullaney, HGA’s national health-care market strategist. “We’re only limited by the number of orders and how fast we get people onboard.”

The modules are approximately 12.5 ft wide by 40 ft long by 10 ft tall. Each contains two rooms, along with ancillary space that can be configured for use as charting stations, staff restrooms, or utilities. The containers are small enough so that they can be easily shipped across the country—even on the back of a flatbed truck.

“This is a true kit of parts that you can assemble in any configuration based on the specific needs of the hospital,” says Spiering.

Everything is sourced from off-the-shelf components. “We designed around what was readily available for everything,” says project manager Kyle Weisman, AIA, NCARB. “But we didn’t sacrifice quality or infection control.”

The modules have a variety of uses. They can be installed inside convention centers or arenas, or they can be placed adjacent to hospitals—in parking lots, perhaps, or on nearby green spaces. In fact, according to HGA, hospitals are looking at these as longer-term solutions once communities pass their peak numbers of COVID-19 cases. The modules can remain on-site as COVID-19 wards to free up permanent hospital space for caring for everyone else. With some medical experts expecting a second wave of the virus to coincide with flu season this winter, having that extra space ready to go could prove critical.

A little further down the line, these modules—which have 10-year lifespans—could be deployed to those hospitals that need additional capacity, converted into exam rooms, or even sent to medical schools for use as health-care simulators. “They are temporary hospitals but not disposable structures,” Mullaney points out.

Reconfiguring Hospitals

The other obvious place to turn to increase capacity are hospitals themselves. For instance, the global construction giant Skanska is overseeing the conversion of two floors of a hospital tower on the Duke University Hospital campus, in Durham, North Carolina, that is still under construction. The floors will house approximately 50 beds for non-COVID-19 patients, freeing space elsewhere for those suffering from the virus. This required coordinating construction activity and logistics so that those floors can be occupied while crews continue work on the rest of the building.

Ben Huffman, a vice president and account manager for Skanska, says staggering work shifts has helped get the job done while protecting worker safety. “Let’s face it … we build,” he says. And “in spite of this crisis, we’ve got to do it safely. That requires direct management of the work on-site.” The team has had to be creative to make the environment safe and comply with guidelines issued by the Centers for Disease Control and Prevention (CDC) as well as local authorities, he says.

Skanska is also working on retrofitting medical-surgical rooms and other rooms into isolation rooms in South Florida, says project executive Nicole Heran. “In a couple of health systems, we’re taking window units out of patient rooms and replacing them with negative air machines.” With the help of its trade partners, Skanska is using prefab sheet-metal duct collars to complete 20 to 30 room conversions per day.

With the help of its trade partners, Skanska is

using prefab sheet-metal duct collars to complete

20 to 30 room conversions per day.

Similarly, Thornton Tomasetti’s Kansas City, Missouri, forensics team is working on a plan to convert regular patient rooms into airborne infection isolation rooms “with the installation of a HEPA-filtered air system,” notes D. Michael Dowdall, P.E., a senior vice president of the firm. “Designed for maximum performance, these negative-pressure HEPA filtration systems provide local pressure monitoring and remote alarm at the nursing station,” Dowdall says. “This allows medical staff to work safely outside the room.”

Many older hospitals were built to house two beds in a room, and while regulations have reduced that number to one in many places, the rooms remain large enough to fit two beds if needed. Underutilized exam and operating rooms normally used for elective surgery could also be repurposed while elective surgeries are on hold. And recently shuttered hospitals could be partially reopened; health officials in Dallas, for example, have prepared 16 rooms at the former Parkland Memorial Hospital, which was replaced a few years ago by a new hospital, to serve patients who need to be monitored for COVID-19 (although those rooms have not as yet been made operational).