The structural complexes used to train first responders must accommodate a wide range of theoretical and practical learning. From classroom spaces to built-to-burn assemblies to buildings within buildings, these special structures must embody cutting-edge designs to be able to be pushed to the extremes by their users.

Public safety training facilities — those complexes at which first responders are trained — must serve many purposes. They are the locations at which recruits are first trained to control fires or stop active shooters and at which veteran safety personnel further hone their specialized skills. They must accommodate theoretical and practical training and include structures that, for example, are robust enough to withstand, almost daily, the extreme heat of a raging inferno or the deluge of pressurized water used by fire-extinguishing equipment. They must also be adaptable; some include structures that can train police to deal with active shooters or hostage situations in schools, homes, or stores. And they often offer places to learn about difficult rescue operations, such as those in elevator shafts or on cliffsides, water, or ice. Above all, these facilities must be able to withstand any number of extreme conditions while keeping instructors and trainees safe and their environmental impact as low as possible.

As is to be expected, recent global design trends have affected how public safety training facilities are designed. There are also specific design trends within the field of public safety that have had impacts. “The key to training now is realism with an eye to the continued safety of the participants,” says Bobby Cummings, P.E., DBIA, a principal in the Roanoke, Virginia, public safety and shooting sports facilities business unit at the architecture and engineering firm Clark Nexsen. “We are leveraging technology to its fullest these days to create the most realistic — but safe — environments.”

Clark Nexsen has worked on public safety training facilities, including military, law enforcement, and private-sector facilities, for three decades. The firm employs a number of design professionals who are also active in the law enforcement, firefighting, or emergency medical services (EMS) communities, according to Cummings. “These are things that we did to give back to the community — all of them are volunteer positions, but they are fully sworn,” he says.

The trend toward realism in training has been driven in part by public involvement.

The design team members at Clark Nexsen use their practical field knowledge to help design training complexes that meet current pedagogical aims. For example, looking at law enforcement training, “in the past it would have been very normal to practice marksmanship and to stand in a fixed position where you could fire at a target—but there was no decision-making, no determining whether to shoot or not to shoot,” Cummings says. “Well, in today’s world, decision-making is paramount. We have to de-escalate the situation to the extent possible, [so] the decision of whether to use force is the first decision that an officer needs to make prior to even deploying any of the tools they have available.

“The training environments must create realistic environments where decisions have to be made and not focus just on testing physical prowess,” Cummings continues. “The same thing is true in EMS and fire service. It is not enough to knock a fire down with water; we need to create realistic situations, realistic venues that emulate as closely as possible [real-world scenarios] while maintaining a safe environment for the public safety professionals to really see what they need to do in terms of their jobs.”

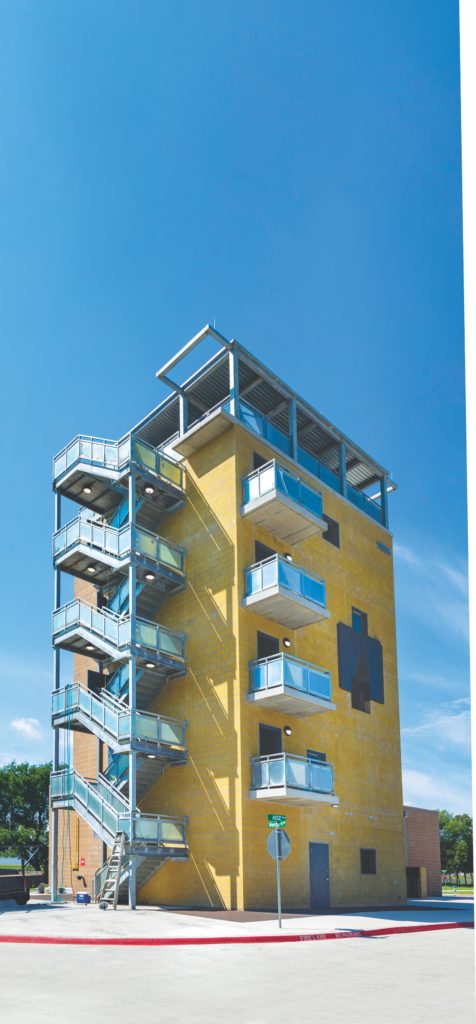

Built-to-burn structures at public safety training facilities contain rooms that use propane-fueled fires for training purposes, such as in the Fort Worth facility. (G2 Solutions Group)

The trend toward realism in training has been driven in part by public involvement, according to Cummings. “Quite honestly, funding hasn’t always been there to the extent that we see it today,” he says. “[However], the media is very quick to point out if a decision in public safety, in their opinion, was right or wrong. With this increased scrutiny I think there is more of a public appetite to spend money on more realistic training venues and provide more realistic decision-making training for our public safety workers.”

To make realistic training scenarios possible while remaining within budget, engineers have opted for adaptable, multipurpose spaces. One example is the new 25-acre Public Safety Training Center (PSTC) at Collin College in McKinney, Texas. The facility officially opened in fall 2018 as the home of two academies at the college, one in fire science and one in law enforcement. It was designed by the architecture firm PBK, of Dallas, with help from the architecture firm G2 Solutions Group Inc., of New Braunfels, Texas, a company dedicated to designing public safety facilities in the United States. Structural engineering was completed by AG&E Structural Engenuity, based in Addison, Texas.

“[The PSTC] is probably one of the most comprehensive facilities for combined police and fire training,” says Mark Graham, AIA, LEED AP, the president and chief executive officer at G2 Solutions Group. Many similar campuses specialize in either fire or law enforcement, he says, even if they “can do” them both. But the PSTC genuinely has all the elements needed for both types of training. “It’s premier,” he says. And the facility can be used to train both new and more experienced

personnel.

The PSTC contains fire science training grounds, a reality-based simulation village for police training, three separate shooting ranges, and traditional classrooms. For fire training, the facility includes a three-story residential and a six-story commercial built-to-burn structures for fire suppression and rescue training, a designated training area for hazardous material spills and fires, a practice area for below-grade trench rescues and earth-collapse scenarios, a vehicle extrication pad, and a civil aircraft fire training area. For law enforcement training, the facility includes indoor shooting ranges; a reality-based simulated munitions training center with adaptable internal buildings that can mimic retail spaces, office buildings, and living areas; and a dedicated defensive tactics room. For the use of firefighters and law enforcement personnel, the facility includes nine classrooms, a gym, and a running track.

For practical training, the facility also includes a mock fire station, according to Graham. “It has everything a real fire station has, attached to the classroom, but the students are actually placed in a real environment,” Graham says. “Part of their class training is they have to cook meals for other students, just like you would in a firehouse.” In addition, “during the course of the day they’ll hear a sound, and people…will actually have to go out to the mock fire station, get in the fire truck, and roll out—just like you would do in a real fire situation.” The complex also includes fully designed streets so that students can practice driving and navigating vehicles as part of this first-responder training.

To emulate realistic construction types and materials commonly encountered by first responders, the facility’s construction is a mix of structural steel, reinforced concrete, reinforced-concrete masonry units (CMU), light-gauge steel framing, and wood framing.

Between the fires and the water used to train the firefighters, the campus’s built-to-burn facilities get the roughest treatment in the complex.

Between the fires and the water used to train the firefighters, the campus’s built-to-burn facilities get the roughest treatment in the complex. “These types of facilities pose many unique challenges not usually encountered in structural building design,” says Ian Babcock, P.E., M.ASCE, a principal of, and studio manager for, the Addison office of AG&E. For example, he says, the buildings must include props that can be used to create large propane fires or back drafts, either of which can be unpredictable but nevertheless must be controlled by an instructor. And they must include rooms that can withstand live burns for advanced fire-related behavior training.

“We’ve completed several of these types of facilities, and through our experience and research, we’ve obtained a better understanding of how to protect the structure through deliberately setting it on fire,” Babcock says. AG&E has been designing these types of facilities for more than 15 years and has determined that these built-to-burn structures must withstand temperatures that can reach 800°F and then drop almost immediately to 70°F. “It’s really quite an undertaking from a structural engineering standpoint,” he says. “It presented a great deal of unique design challenges beyond the building code requirements, but we start with the building code to give us a baseline, and then we use our own experience to better understand the anticipated loading and demand on the structure, and analyze it from that point forward.”

Fire loading can reduce the capacity of the reinforced-concrete members by up to 60 percent, according to Babcock. “Essentially, what we had to do was increase the cover of the concrete to help protect the reinforcing, increase the reinforcing, [and] use larger concrete members than we normally would,” Babcock explains. Water loading and saturation also had to be accommodated. “Concrete obviously cracks, and the last thing one wants is all of this water reaching the reinforcing in the concrete and causing corroding of the reinforcing,” he explains. The design team’s solution for the PSTC’s built-to-burn structures was to use materials and designs typically used in high-water environments, such as for bridges and wastewater facilities.

For the most part, the interiors of built-to-burn buildings are utilitarian. “We don’t deal with finishes inside of the buildings, so you’ll see exposed concrete masonry block,” Graham says. However, in specialized “Class A” rooms, real fires are created using plywood or other materials, depending on what is being studied, according to Graham. These rooms can be used for advanced training in arson and how to recognize what is burning by the color and behavior of the flames. This prevents firefighters from endangering themselves or others by, for example, trying to put out a phosphorus or grease fire with water, or rushing into a chemical fire that is moments from exploding. While in use, these rooms can reach 1,200°F at the ceiling level while the walls range between 600 and 800°F, according to Graham. Because of this, the walls and ceilings are protected with a heat-resistant lining system, which could be concrete refractory tiles (as were used in the PSTC), metal, or calcium silicate boards.

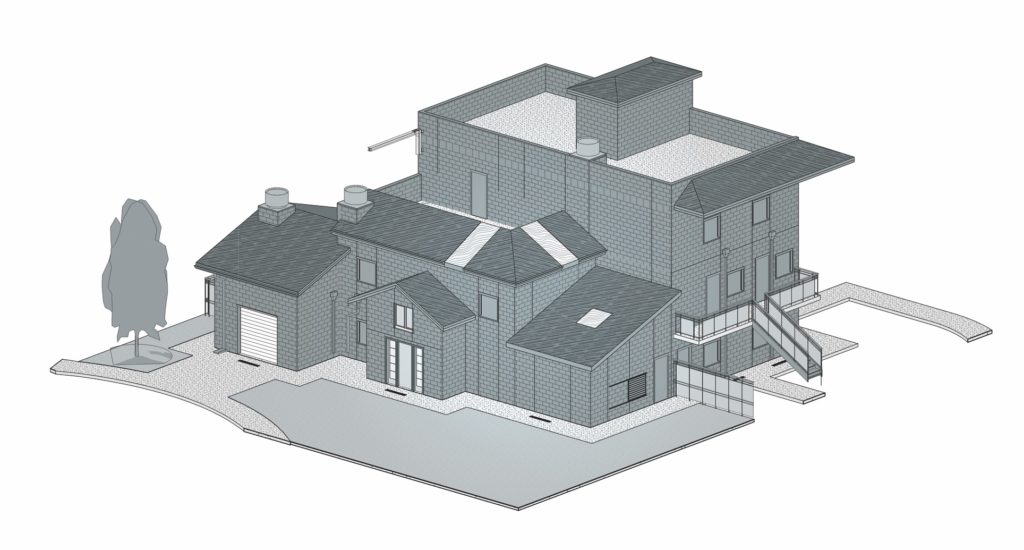

The Collin College facility comprises classroom and administrative space, residential and commercial built-to-burn structures, and a mock fire station. (Collin College/Nick Young)

On the law enforcement side, the PSTC’s reality-based training village is designed for weapons that use simulated munitions, according to Babcock. The village is located within a large warehouse-style building with an interior village that includes city streets, signs, mailboxes, and blind corners. “The shell of the building is comprised of twelve-inch-thick, load-bearing CMU walls and forty-four-inch-deep, long-span steel bar joists, which span approximately sixty feet over the top of the area,” Babcock says. “Since the interior of the building is designed to be totally reconfigured, column placement was critical and required extensive coordination between the structural and architectural teams.” The perimeter of the building uses load-bearing CMU walls to reduce the presence of steel columns inside the training area. “The original goal was to clear-span the one-hundred-and-twenty-foot-wide space, but due to the depth of the roof joists that are required to span this distance, a series of steel columns and roof beams were strategically hidden in the permanent portions of the structure and placed near the center of the [testing] area to reduce the roof span by half,” Babcock says.

“The structural shell of the interior simulation training village is designed to replicate actual real-world building types to provide police officers with the most realistic and nonlethal, force-on-force training conditions,” Babcock explains. To offer these building types—which include a school, a bank, a doughnut store, a check-cashing business, and a two-story apartment—the interior of the building includes freestanding panel walls that can be reconfigured to create various interior room and hallway layouts.

The need for realistic training brings with it the need for design teams to stay up-to-date on architectural trends.

The need for realistic training brings with it the need for design teams to stay up-to-date on architectural trends. “It used to be that these training structures, whether it was law enforcement or fire, were simple,” Graham says. “If you drove by, you would see a box building that was maybe four stories tall, and it was literally a forty by forty [ft] box, and you’d think, ‘Oh, that’s where they train.’ But that doesn’t simulate the real world.” Today’s cutting-edge training facilities—including the PSTC—train first responders with a variety of types of structures, be it the pitched roofs and attic spaces of residential buildings or the open spaces and rooflines of warehouse, industrial, or retail buildings.

To familiarize trainees with the appearance and behavior of different types of structural roof frames, the PSTC includes a structure that exhibits five types of roofing within an area of 50 by 80 ft. Three of them are common residential styles and two are common commercial or educational styles, according to Babcock. The residential styles include a wood-sheathed roof on wood joists, a wood/plywood sheeting roof atop 20 in. deep wood trusses spaced 24 in. apart on center, and a 1.5 in. thick, 20-gauge metal roof on top of 10 in. deep, light-gauge, cold-formed metal roof joists spaced 42 in. apart on center. The commercial examples include a 1.5 in. thick, 20-gauge metal roof on steel beams and a similar metal roof deck on steel bar joists. “We had five different roofs within a few feet of each other that were similar in area for each roof,” Babcock says. “It’s actually a great training exercise for structural engineers as well, just to be able to see the different roof systems adjacent to each other and the distinct and unique design challenges associated with each one.”

Depending on a site’s location and regional attributes, its specialized training will differ. While the PSTC has specialized training in hazardous spills and confined-space/trench rescues, for example, a training facility in Colorado might include a rock-climbing wall to offer rescue training for hikers who might have become lost or injured in the Rockies, according to Graham. “People forget, [that] the guy who came to your house and performed CPR [cardiopulmonary resuscitation] last week may be the same guy who is going to have to rappel down the mountain or climb up to rescue a stranded hiker,” Graham says. “That’s a firefighter.” Certain California facilities might have specialized training in wildland fires, while coastal areas might have lifeguard training, and areas prone to subfreezing temperatures might have training for ice rescues. Those in urban areas will include specialized training in high-rise elevator rescues.

WHILE IT MIGHT SEEM obvious that these training facilities must be designed to be safe, the definition of what safe means—and how to design for it—is undergoing a shift. While the structural integrity of the buildings is a given, there has been increased emphasis recently on the safety of users, especially with respect to mobility within a structure and contamination control.

This year the National Fire Protection Association (NFPA) released its first standard on fire training facilities, NFPA 1402: Standard on Facilities for Fire Training and Associated Props. The standard evolved from a series of guides that the NFPA has developed, updated, and published periodically since 1985. The consensus-based standard catalogs the industry’s best practices for the safe, effective, and efficient design and construction of modern fire training facilities and their various component buildings, with information about details as small—but crucial—as the mounting systems for rappel training and as large as the design and engineering of built-to-burn structures.

“Our standard doesn’t just include the classroom or the physical building where the knowledge or instruction takes place, it also includes places where simulations can occur for hazardous materials or bioterrorism events [or] where we can work with collapsed structures but in a controlled, safe way, so that it is not with all the hazards and variables that you would actually encounter,” says Peter M. Schecter, the chair of the committee responsible for developing and revising NFPA 1402 and who is a safety supervisor at JetBlue Airways in Fort Lauderdale, Florida. “We need to help people design things that provide a challenge that is realistic but also don’t present a challenge to the degree that we can’t somehow control it. In some ways [we need to] literally have a big, red button that says ‘stop,’ so that if someone has a problem or they are not responding well, we can stop the exercise or the process and then restart it.”

In fact, Schecter adds, “The biggest, most acrimonious thing that the committee dealt with—and they did so very bravely, so kudos to all of them—is the life safety of the users. We’ve had, throughout the country and the world, tragic events that occur during training. Typically, it’s fire suppression training.”

the new edition of NFPA 1402 requires that there be two means of egress for every room used for fire suppression training in new designs.

For this reason, the new edition of NFPA 1402 requires that there be two means of egress for every room used for fire suppression training in new designs. While retrofitting older training buildings to include two egresses is not required, Schechter hopes that owners voluntarily make the commitment to do so because if a trainee working in a burning room falls and blocks the only door out, the entire crew could become trapped inside. “We’re prepared to receive a little bit of backlash because it’s going to be expensive and hard to retrofit existing buildings for people to have two means of egress from every burn room on every level of a structure,” Schecter says. “It’s an engineering challenge; it’s going to take time and money and ingenuity to do that. But we think it’s something that they can overcome, and we felt strongly enough about it that we wanted to include it.”

Contamination control, both in the field and in training facilities, is also a growing topic of concern within the industry as a whole. Many firefighters and other first responders, regardless of how far into their careers they are, are “developing a lot of really severe cancers that are directly related to exposure to carcinogens that we now know comes from almost any kind of fire and in some cases even our own vehicle exhaust,” notes Schecter. As a result, the 2019 edition of NFPA 1402 requires that centers be designed to meet personal gross decontamination needs, so that particulates can be removed from both people and gear, explains Michael T. Wixted, an emergency services specialist in NFPA’s emergency response and responder safety division and the staff liaison for the standard.

“It used to be a badge of honor…to come back and have the firehouse smell like smoke because of everybody’s gear; those days are gone,” Schecter says. “We need our people to realize that it’s like going to a…chemical emergency or a biohazard emergency or a terrorism event, where you go in and the outer layer of your personal protective envelope is contaminated now, and you need to take it off carefully.”

This need, which is being widely publicized by the city of Boston as it works to protect its future generations of firefighters, extends to training facilities as well. “[Even if] we use gas-fired training, which is a little bit cleaner looking, it still results in the same contaminants being generated by the process of combustion,” Schecter explains. “So we have a lot of engineering going into having a very [strong] line of demarcation between clean and dirty. We need to make sure we create an environment and build the systems in to capture that dirt and keep it out of the clean side of the building, and that helps keep our people healthy. So that’s a very big push.” Including spaces in the design in which gear—and bodies—can be decontaminated is crucial to this effort.

Safety and contamination are issues that also need to be considered in law enforcement training, though to a lesser extent. This is of particular concern in shooting ranges, though adequate ventilation systems and acoustic management typically can resolve the issues for indoor ranges, according to Graham.

Sometimes, creating safer ways to train first responders can also take place by removing them entirely from the real world, instead using the rapidly improving offerings of virtual and augmented reality. Using such technology enables highly specialized training to take place without the need to put students—be they beginner or advanced—into unsafe physical scenarios.

The city of Wilmington, North Carolina, broke ground in fall 2018 on its future Haynes/Lacewell Police and Fire Training Facility, which combines live training and immersive virtual training, and while it will be primarily used for the city’s police department, it will also be used by its fire department, according to Cummings, who was the principal in charge of the project for Clark Nexsen, which designed the facility.

In addition to driving simulators and a command center simulator for police and firefighters, there will be “a law enforcement simulator that will be a nearly 360-degree immersive environment that will allow police officers to make decisions based on the actions of subjects within that simulator,” Cummings notes. The simulator will also be responsive to users’ decisions, so the scenarios can go in multiple directions based on the users’ choices, he says.

Immersive virtual training can also be used to train firefighters. “It’s something that we can use to condition people, because a lot of our training is mental training, to recognize or react, as opposed to actual hands-on skills that they need to perform,” Schecter says. “So if I can get someone to wear a representation of the breathing apparatus (face mask) and give them a virtual reality view through a building, their decision-making process can be reinforced before they even get to the fire scenario.”

AS INTEREST IN ENVIRONMENTAL protection is growing worldwide, such concerns are also making a difference in new public safety training facilities. For example, on all property owned by the Federal Law Enforcement Training Center (FLETC), “all new construction and/or major renovations are designed/constructed to achieve at least Leadership in Energy and Environmental Design (LEED) Silver certification,” said Jannett Bradford, Ph.D., the acting deputy assistant director of the Mission and Readiness Support Directorate at the FLETC, who wrote in response to questions posed by Civil Engineering. Founded in 1970, the FLETC is one of the United States’ largest providers of law enforcement training.

Other facility concerns that must be managed through design include the quality and quantity of water used. Coastal communities tend to have strict disposal requirements, according to Graham, because even if water is potable, the trace amounts of chlorine that it contains can harm fish. And more significant environmental and human impacts arise from the use of firefighting foam, which contains perfluorooctanoic acid (PFOA). To keep these contaminants from potentially entering groundwater when training with foam, “we also have to [design] building systems to collect and treat anything that we use,” Schecter says.

In addition to the quality of the discharged water, the design team must also address the quantity of water that will be used. “The one thing that keeps coming up…has to do with how much water a facility uses and what they do with the water,” Graham says. “Fire training facilities use a lot of water. I’ve had facilities use upwards of two million gallons of water a year, which some people would say doesn’t seem like a lot, but if you’re in a drought situation and you have to drive by and you see firefighters blowing water out of a hose and they’re shooting a thousand gallons a minute, and you can’t water your lawn, of course it’s a big issue. That’s a lot of water.”

water capture and reuse systems are built into many training facilities.

As a result, water capture and reuse systems are built into many training facilities. The $101.5-million Bob Bolen Public Safety Complex in Fort Worth, Texas, which houses the training facility and headquarters for the city’s fire and police departments and was completed in 2015, includes a retention pond on-site to capture and reuse water, Graham says. Collin College’s PSTC also includes a retention pond for water capture and reuse. In general, when designing these systems, Graham says, “We collect all the water used in fire training, and it goes back to the pond, gets filtered, and we pump it back through, and then we reuse it. I’ve done several facilities with those, but I always have to caution people…you’ve got to be able to have a pond that can hold anywhere from seven hundred thousand to a million gallons of water. Because while you’re fighting fires, fifty percent of the water that you emit onto a flame is going to be absorbed into steam or it’s just going to burn off.”

The ponds must also be carefully detailed so that they do not become, for example, mosquito breeding grounds in hot, humid climates or unusable because they have frozen over in areas with long, subfreezing winters. In some instances, Graham notes, designers can actually create a multipurpose system in which the water in the pond or the ice that forms atop it can be used for training purposes—but such designs have to be done with the safety of trainees amid all usage scenarios in mind.

As architecture and engineering design trends change, so do the design of public safety training facilities. One example of this is the growth over the last three to four years of mixed-use multistory buildings that include full retail floors at ground level with residential housing atop. “For a firefighter, that is a total nightmare,” Graham explains. “Because if on the first floor you’ve got a commercial kitchen [grease] fire and housing above it, that’s all kinds of problems.” Firefighters must know how to best to approach such a fire and extinguish it while protecting the residents that it might impact. Another growing design trend that firefighters must now be able to quickly handle is rooftop solar panels. “Most people don’t even think twice—it’s a great thing!” Graham says. “But you don’t think about [the fact] that a firefighter that has to go up on the roof, and all of the sudden he gets up on the roof and it’s a sea of solar panels. What do you do?

“Every time the trends across the United States change, that’s the great challenge, [and] that’s what I enjoy,” Graham says. “It’s about learning how to take that and put it into a training scenario.”

This article first appeared in the April 2019 issue of Civil Engineering.