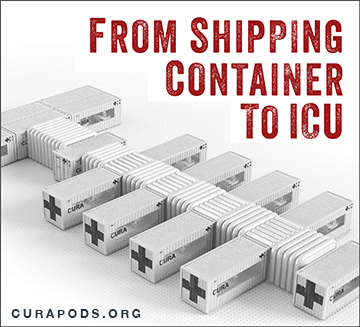

A NONPROFIT COALITION of architects, engineers, doctors, and other experts has launched a method for turning freight shipping containers into intensive care units (ICUs) to treat patients with COVID-19.

Called CURAs (connected units for respiratory ailments), the pods are as easy to set up as medical tents but provide the added protection of negative air pressure, according to a March press release issued by Carlo Ratti Associati (CRA), the Italian architecture firm spearheading the design. Each 20 ft long CURA pod will contain all the medical equipment needed for two ICU patients, including ventilators and intravenous fluids stands, the release states.

The first prototype, funded by the European bank UniCredit, is undergoing construction in Turin, Italy, and will be connected to an existing hospital. Construction is expected to be completed before the end of April. CRA is working with the international engineering firm Jacobs as well as Italian architect Italo Rota, among others, on the project.

Shipping containers are easy to obtain, according to Carlo Ratti, the founding partner and chair of CRA and the director of the Massachusetts Institute of Technology Senseable City Lab, which is contributing research to the pods. In choosing to use shipping containers to house medical beds, Ratti says, “Our objective is not to invent something necessarily new. Rather, we want to improve the efficiency of existing solutions in the design of field hospitals, taking into account what is most needed in the framework of the coronavirus pandemic.

Shipping containers are easy to obtain, according to Carlo Ratti, the founding partner and chair of CRA and the director of the Massachusetts Institute of Technology Senseable City Lab, which is contributing research to the pods. In choosing to use shipping containers to house medical beds, Ratti says, “Our objective is not to invent something necessarily new. Rather, we want to improve the efficiency of existing solutions in the design of field hospitals, taking into account what is most needed in the framework of the coronavirus pandemic.

“The interesting thing about shipping containers,” Ratti adds, “is that they can be easily sourced in large quantities all across the world.” They can also be readily moved by train or truck, he adds.

The CURA pods have drawn interest from entities across the globe seeking to increase their hospital capacity in the face of the pandemic, Ratti says, “with a significant number of requests coming from countries in Europe, the Middle East, and Latin America [as well as] the United States.”

The pods are based on an open-source design that others can alter and customize to their needs. “While the basic goal is clearly the same—raising the ICU capacity—we are looking for suggestions to address specific needs,” Ratti explains.

Modular Design

Each pod can operate autonomously, or the units can be connected to one another by an inflatable structure. Together the complex can then stand alone or be connected to an existing hospital. It can take a matter of just hours to build a 4- to 40-bed configuration, according to the press release.

The inflatable connector structures are made of fire-resistant, polyurethane-coated nylon. “They are connected to the pods by a double closure system, with a first flap over the perimeter of the container entrance and a second, fabric flap over the external perimeter,” Ratti explains.

Jacobs is consulting in the areas of layout and master planning; biocontainment; functional design; mechanical, electrical, and plumbing review and development; utility connection; and distribution, according to Leah Shoats, Jacobs’s communications manager.

“We were thrilled to have the opportunity to work with Jacobs,” Ratti says. “They have been providing engineering-specific expertise to the design team, especially as we look to scale up the project to have a wider impact. They have been contributing to the design development of the architectural concept, [taking it] into an engineered layout, and [conducting] master planning for different configuration sets.

“Among other things, they also helped coordinate technical design efforts with the design team and [helped with] potential external suppliers for technical solutions to speed up the process.”

Those wishing to contribute to the designs—or learn from them—can visit CURApods.org. Ratti says, “Every idea on how to improve the prototype is welcome!”