XYZ Reality, a construction-based augmented reality company in London, is in the process of testing a new holographic headset that has the potential to eliminate the use of 2D drawings on construction sites. The HoloSite system, which employs a project’s existing building information modeling (BIM) and site coordinates, is expected to launch in mid-2021.

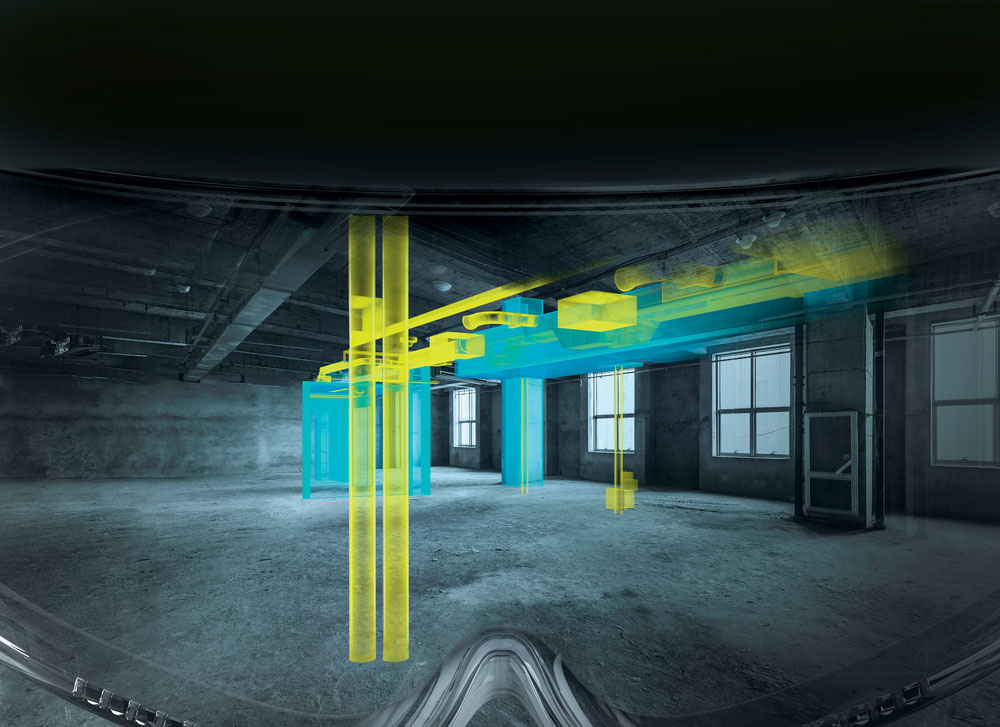

The HoloSite system is viewable through a dedicated headset, which enables workers and managers to overlay 3D models on real-world construction sites. This means that projects can be assessed in real time and built to within 3 mm accuracy of the design plans, according to David Mitchell, the founder and chief executive officer of XYZ Reality.

Its development stems from an experience Mitchell had as a digital construction manager on a data center project in Ireland. “We landed on-site with one hundred fifty men and no drawings to build from,” Mitchell says. It took four workers — including Mitchell — three days to generate enough drawings for one day’s worth of on-site work. In an effort to streamline that process—and building off a paperless construction system that he had already been working on—Mitchell used data from the project’s BIM Level 2, a government-mandated standard in the United Kingdom that determines how data are managed and shared among stakeholders. Data for the underground site works were imported into a total station surveying tool to create 3D models for construction use. “When we made the switch, it actually took me twenty minutes [to create the models] to keep the site going for three days, so it was a complete turnaround and a massive success,” he says. “And there were actually five-time increases in setup-to-build efficiency in the field as well.

“That [experience] was really the driving factor,” Mitchell says. “I turned to my employer at the time, and I said, ‘Look, I’m really pushing this — I’m going to found a business, and I think buildings can be built from holograms in the future.’” His then-employer, J. Coffey Construction Ltd., based in the United Kingdom, agreed with the significance of the effort, becoming the first investor in the business, Mitchell says.

Leveraging computer science to alleviate construction and engineering challenges is an important next step in moving engineering into the future, according to Ioannis Brilakis, Ph.D., M.ASCE. He is the Laing O’Rourke Reader in Construction Engineering in the Department of Engineering at the University of Cambridge in the United Kingdom. Brilakis is also part of the university’s Centre for Smart Infrastructure and Construction but is not involved with XYZ’s work.

Brilakis believes that it is time for those in the field of civil engineering and the built environment to better digitize their workflows so that artificial intelligence and virtual or augmented reality can be better utilized in their work.

And this is precisely what the creators of HoloSite hope to do.

The tool is different than other augmented-reality devices because it situates its model using a construction site’s existing coordinates, which are established on-site by surveyors, as control points for construction. This provides an absolute position on which the hologram can be based, Mitchell explains. “All the other technologies coming out are actually using a relative positioning system,” he says. “(But) when you have a two-hundred-millimeter error on a referenced object, then your hologram is out by two hundred millimeters.”

The company has conducted on-site field tests to fine-tune its system before launch, improving its accuracy from 5 mm to 3 mm in recent months.

XYZ has done a number of studies to establish the usefulness of HoloSite. That work has shown that building from a 3D hologram rather than a 2D drawing offers significant cost savings because the number of on-site construction errors are reduced, according to Mitchell. “You see a substantial amount of projects — up to 98 percent of megaprojects — run over in costs by more than thirty percent, and about seventy-seven percent of megaprojects are over forty percent late,” Mitchell says.

“We went out and we scanned a number of projects around Europe, and we actually found that up to eighty percent of construction works are built out of tolerance. Not by five or ten millimeters but two hundred to four hundred millimeters,” he says. This is, in part, because once an early stage of construction is built incorrectly, there is a cascading effect as later stages are redesigned to accommodate that initial mislocation. “So when you think about the errors propagating now that you’re out on-site, it’s a big red flag and perhaps a big contributor (to) why we’re not able to deliver (projects) on time and on budget,” Mitchell says.

HoloSite eliminates the need for redesigns and rework by enabling workers to overlay the design model on the site at the “lowest value stage,” as Mitchell describes it. Rather than a laser scan conducted after a phase is complete that reveals, for example, that ductwork and concrete are located 200 mm off the design specifications, the construction manager could simply use the HoloSite goggles to make sure the ductwork is positioned correctly as it is installed and before the concrete is placed.

The design model is configured so that all disciplines can be viewed. It is easily updatable, which means that any design changes that might occur during a project can be integrated into the hologram as desired.

XYZ has studied the amount of time that construction managers spend in offices compiling and interpreting information from drawings, scans, emails, and photos as they oversee projects. The goal is to consolidate all that information into an easily digestible, visual model. “This provides all the context you require out in the field, and it allows managers to stay on-site for longer periods of time and ensure the works are getting done correctly,” Mitchell says.

The company has conducted on-site field tests to fine-tune its system before launch, improving its accuracy from 5 mm to 3 mm in recent months.

The opportunities for cost savings have also been proved. During testing of HoloSite on a recent data center project in Sweden, XYZ saved the general contractor about £100,000 (U.S.$127,000) in rework costs by discovering that the fiber ducts coming into the building had been placed about 500 mm off their design locations — just before they were backfilled and concrete was placed. “There was a five-minute period where people were like, ‘Your headset is wrong,’” Mitchell says. But when the findings were double-checked using a total station, “the trade contractors were then turning to us and going, ‘Can you check my work?’ Because no one wants to build it wrong in the first place,” he says. “And that’s when we really won over

that site.”

The system is easily updatable, which means that any design changes that might occur during a project can be integrated into the hologram as desired.

XYZ recommends that a site use between three and five headsets, depending on a project’s size. Workers wearing the sets will be able to communicate with one another while doing so. “When you’re reading a drawing and somebody else is reading that drawing, there can be some ambiguity or misinterpretation,” Mitchell says. “Whereas when you’re both looking at a hologram position accurately, you’re all on the same page, right? And you can actually start to problem-solve out in the field.”

Individuals or large groups have the option of remoting into the headset’s view via computer. “Remote-assist has been very popular (during testing),” Mitchell explains. “We’ve had up to forty users remotely logging in to a walk-down on-site, for instance,” he says.

XYZ hopes that HoloSite will also help in the creation of high-fidelity digital twin assets that can be handed over to the client after construction for use in operating and maintaining the structure. Engineers would be able to base the digital twin on the complete and highly accurate construction model, rather than needing to create a quick digital as-built model postconstruction.

This department first appeared in the September 2020 issue of Civil Engineering.

Super, awsome technology