A series of breakwaters to protect a coastal wildlife refuge in southwestern Louisiana incorporated an innovative, lightweight design. Despite extremely poor soils and ongoing erosion that kept changing the shoreline throughout the project, the breakwaters are already showing dramatic results.

The Rockefeller Wildlife Refuge in southwestern Louisiana, which borders the Gulf of Mexico for 26.5 mi, is disappearing at an increasingly rapid rate. When it was created in 1920, the refuge originally encompassed 86,000 acres of biologically diverse coastal wetlands in Cameron and Vermillion Parishes. But over time, ongoing coastal erosion has reduced the refuge to 71,000 acres.

Twenty years or so ago, a key 9.2 mi stretch of the refuge was losing about 50 ft of land per year, notes Phillip “Scooter” Trosclair III, a biologist program manager for the Louisiana Department of Wildlife and Fisheries, which manages the refuge. The rate of loss in that region increased to around 70 ft a year, then 100 ft, and then by 2016 surveys indicated that more than 300 ft of land had disappeared in a single year, Trosclair says. People worried that “if we keep getting hit with this pattern, we’re not going to have any land left,” Trosclair recalls.

But even as the refuge seemed in greater danger, a solution was already in the works. When erosion losses started to accelerate around 2000, the Rockefeller Refuge Gulf Shoreline Stabilization Project was taking shape. Implemented by the Louisiana Coastal Protection and Restoration Authority and the National Marine Fisheries Service — the local and federal sponsors, respectively — the stabilization project focused on that heavily eroding 9.2 mi long section of the refuge, which is located entirely in the Cameron Parish portion of the site. Known as ME-18, according to its designation under the Coastal Wetlands Planning, Protection, and Restoration Act, the stabilization project is a $33 million-plus effort to protect the refuge shoreline by constructing a 4 mi long series of breakwaters.

HDR Engineering Inc. was the lead design firm, working for CPRA. The general contractor was LeBlanc Marine LLC, now part of Patriot Construction and Industrial LLC.

Additional breakwaters are planned as parts of future projects that could ultimately extend protection along the full 9.2 mi length of the most endangered portion of the refuge.

Between the early 2000s and 2020, the design and construction of the stabilization project went through multiple iterations and had to overcome numerous challenges, including the need to repeatedly compete for available construction funding that is awarded only once a year, “which can cause years of delay,” says Bevin Barringer, P.E., a CPRA engineer and project manager. Moreover, obtaining funding for this sort of land protection effort can be a “hard sell,” says Trosclair, “because there are so many unknowns: Will it really work? What are the cost benefits? How much land will be reclaimed? Do we know for sure we’ll actually protect much?”

Meanwhile, Hurricanes Rita in 2005 and Ike in 2008 caused additional damage along the Gulf Coast; Ike alone resulted in roughly a full year’s worth of erosion in just a few days. Hurricane Katrina, perhaps the most infamous storm of the period, struck further east and did not have much impact on the refuge.

One of the greatest challenges the designers of the stabilization project faced was the site soil conditions, which at the surface feature a few feet of shell hash — formed from crushed shells of oysters, clams, or other bivalves — atop about 40 ft of very soft clay. The sun-bleached shell hash might look like sand, but it is actually a very lightweight material that gets easily washed around by wind or wave action, notes Brett Geesey, P.E., an HDR office principal.

“When you get a high tide or get strong wave energy, (the shell hash) moves and smothers the vegetation, and then when the next frontal system comes in and the winds pick up to 20 mph and you get 6 and 8 ft waves, that moves the shell hash another 30 to 40 to 50 ft inland,” explains Trosclair.

“So where (the land) was a week before, it’s now all dead. (There is) no more vegetation, just stubble in a high organic mud flat. Then the erosion process comes in because there’s nothing there to protect it, the roots are dying, there’s no more plant mass, and so it breaks apart rapidly,” Trosclair continues.

The site’s poor soil conditions were confirmed by Fugro, the geotechnical engineer, which initially drilled 20 borings at depths of 25 to 100 ft. Later, another nine borings were drilled, each to a depth of 25 ft, and six field vanes were drilled 20 ft deep. Other sampling measures were also used, “generally located on a line approximately parallel to the shoreline,” according to HDR’s October 2014 final design report, Rockefeller Refuge Gulf Shoreline Stabilization (ME-18). Budgetary limits “restricted field investigations to land and shallow water only — no borings or probes were performed from floating plant. However, 100 grab samples were obtained from the seafloor within about 2,000 ft of the shoreline,” according to the report.

As the stabilization plans developed, the design team considered more than 50 alternate proposals, including breakwaters, revetments, beach refurbishments, and other shoreline strengthening and protection techniques. That number was gradually narrowed down because of costs, constructability, and other parameters to just four finalists that would be tested through demonstration projects, Geesey says.

The four demonstrations included two types of breakwaters — a traditional reef-style breakwater and one with a core formed from a lightweight aggregate — spaced approximately 2,200 ft apart so that the two structures would not affect each other. There was also a beach nourishment approach using gravel as well as a system of concrete panels similar to a sheet pile wall system. The concrete panel demonstration was dropped because of the tight budget, but the other three systems were constructed in 2009 as part of a $9.3 million contract awarded to Choctaw Transportation Co.

For the next year, the design team monitored and evaluated key features of the three demonstration projects using various methods, including wave gauges on the seaward and landward sides of the breakwaters “to understand the waves coming in and impacting the features … and to understand how much (the projects) actually dampened the wave energy,” says Geesey.

The teams also used water level gauges and surveying “to understand the impact to the shoreline, both on the projects and adjacent to the projects,” Geesey notes. Aerial photography and ground-based visual inspections also helped “to see if there was anything of note happening,” he adds.

The gravel beach project did not perform well. Placed atop the existing beach, the gravel layer was designed to shield the underlying soils. But the gravel “moved around more than we intended, and it ended up being fairly expensive,” Geesey says. Measured between February 2010 and March 2011, the gravel beach project experienced a loss of more than 84 ft of land, which was twice what the teams had predicted.

The reef-style breakwater, which was wider but lower in elevation than the breakwater with the lightweight aggregate core, also fell short of expectations. “It was too heavy and settled too much and didn’t break the wave energy we needed it to,” Geesey explains. It lost nearly 18 ft of land during the demonstration period.

Only the lightweight aggregate core breakwater, which lost only 3 ft of land, “met all our criteria,” Geesey says. HDR had used LWAC breakwaters previously in Louisiana, he notes, but only in interior water systems — never before along the open, fully exposed gulf shoreline.

A control area without any demonstration projects lost roughly 45 ft of land, which matched historical erosion rates.

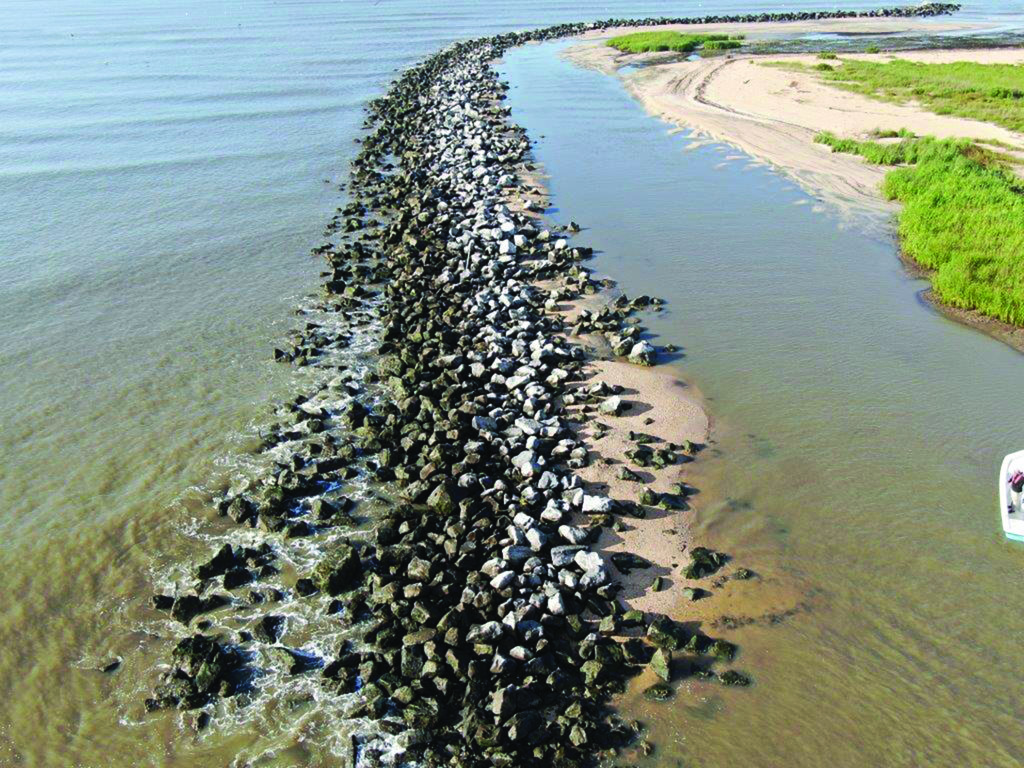

The roughly 500 ft long LWAC demonstration breakwater was upscaled to a series of 1,500 ft long segments constructed in about 3 ft deep water approximately 150 ft offshore, although the exact alignment shifted throughout the construction phase because the coastline kept moving northward as a result of the ongoing erosion. The breakwater segments were separated by narrow gaps to enable a natural flow of water and provide access for fish and other marine life.

The LWAC demonstration breakwater was left in place and incorporated into the overall project, but the traditional reef-style breakwater was removed and replaced with the LWAC design, says Dion Broussard, P.E., a CPRA engineer. The project also incorporated an existing artificial reef — from a separate demonstration project but located along the western end of the planned LWAC breakwater alignment — that consisted of interlocking concrete rings designed to create an oyster habitat.

The typical LWAC breakwater structure is roughly 60 to 70 ft wide at the base, 18 ft wide at the crest, and approximately 6 to 7 ft tall. The inclined sides typically feature a 2:1 horizontal-to-vertical slope. The subgrade material beneath the breakwaters was not manipulated in any way, Geesey says, because “we didn’t want to disturb the existing soils any more than we had to.” The breakwater rests on a geotextile composite material secured to the underwater ground with bedding stone on the landward and seaward toes of the structure.

The heart of the breakwater — figuratively and physically — is the LWAC, which consists of stacks of bags made from a woven geotextile fabric and filled with the aggregate material. Each bag holds approximately 5 cu yd of aggregate, which is a type of clay that is cooked in a kiln to remove all the moisture, creating “these little, lightweight but very hard balls of material,” says Barringer. There are not many producers of the product, she adds, but fortunately a plant near Baton Rouge, Louisiana, was able to supply the volume of aggregate the project required.

Filled off-site and transported to the construction area by barge, the bags had to be carefully grabbed with a special attachment on a material handler to avoid damaging them and then stacked in a roughly triangular cross-section arrangement developed by the contractor. Another layer of geotextile material was placed over the aggregate bags to secure and protect them and then the breakwater was capped with large armor stones weighing from 1,000 to 5,000 lb apiece. “The aggregate is really light, which is why we used it,” Geesey notes. “But if left exposed, the waves could move those big bags around.”

The contractor used multiple barge-based rigs on the gulf side of the breakwater alignments to construct the individual breakwater segments, which began at an inlet of the Joseph Harbor Canal and moved westward. Although the project was initially funded for just a 3 mi length of breakwaters, the winning construction bid actually came in lower than expected, which enabled the project to extend the breakwaters by an additional mile, Geesey says.

The constantly eroding shoreline was perhaps the greatest recurring challenge of the project. Anytime there was appreciable downtime for weather or other issues “that caused delays in getting the armor rock down, the shoreline going to the west continued to erode,” says Geesey. New surveys had to be conducted every few months throughout the construction phase.

Initially the plan was to conduct new surveys every three months, says Trosclair, but “you really had to get it in much quicker so you could get (the work) established before there was another change.” That meant the time frame was closer to new surveys every two months. “The contractor came up with an assembly-line-type procedure to get the rock installed as quickly as they could,” Trosclair adds, “because the landscape was changing so much.”

Settlement plates — metal poles installed in the breakwaters — will be used by surveyors to periodically measure the LWAC structures for settlement, notes Broussard. And the shoreline will be monitored for any accretion of new land from sediment captured by the breakwaters. Such accretion has already begun “pretty much everywhere (the breakwaters) were constructed,” says Barringer.

In fact, the breakwater project is working so well that Trosclair first noticed improvement during the demonstration phase. Sediment “actually built up enough (behind the LWAC demonstration structure) that you could walk from land and touch the rocks, where before there had been 3 ft of water,” he says.

And the sediment buildup is continuing behind the completed LWAC breakwater segments. Much of the new material is still shell hash, Trosclair says, but he is also starting to see silt and sand collecting behind the breakwaters. Together, these new materials are “becoming more stabilized, more compact,” he notes. “It’s not as loose as it had been before the shoreline protection.” Moreover, he adds, “We’re seeing vegetation beginning to establish, and the shell hash is actually building up in elevation and not moving.”

The sediment buildup is a welcome side benefit of a program that was primarily focused on just stopping erosion, says Geesey. Moreover, the success of the LWAC breakwaters was both fortunate for the refuge and a nice change from prior experience. “In the past, many breakwaters constructed in Louisiana left a bad taste in people’s mouths because they settled so much,” explains Barringer. “After they settle under the water, they become more of an obstruction that doesn’t do anything to protect what it’s supposed to protect. So the fact that we were able to come up with this (LWAC) approach, I think, will hopefully make this type of hard structure a little more feasible in the future.”

Additional projects funded by Cameron Parish and others are already planned, including an effort under construction to extend the breakwaters about 3,000 ft to the west. The existing LWAC system has stood up well to the various hurricanes that struck the region this year, although at press time a survey was planned to confirm that assessment.

PROJECT CREDITS Rockefeller Wildlife Refuge manager Louisiana Department of Wildlife and Fisheries ME-18 project federal sponsor National Marine Fisheries Service ME-18 local sponsor Louisiana Coastal Protection and Restoration Authority ME-18 project managers Louisiana Coastal Protection and Restoration Authority and the National Marine Fisheries Service Lead designer HDR Engineering Inc., Lafayette, Louisiana office General contractor LeBlanc Marine LLC, now part of Patriot Construction and Industrial LLC, Duson, Louisiana

This article first appeared in the January/February 2021 issue of Civil Engineering as “Protecting a Refuge.”